Design Process

- Home

- Our Business

- Design Process

Solution - Value Analysis

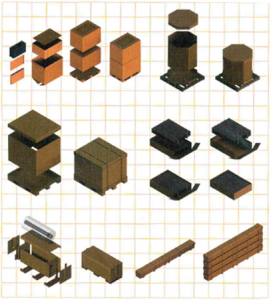

Aiming to reduce 20%* in total cost and 50%* in environmental burden. (*Compared to wood packaging)

Through our Fabricator Network, we provide consultation and service support at customers’ request. By conducting a systematic Value Analysis, we target an initial total cost reduction of 20%* and a reduction of environmental burden by 50%*.(*Compared to wood packaging.)

VA Flow

- Analyze current packaging system for improvement

- Establish points of current system to be improved and propose design to implement those improvements

- Design and produce prototype pack

- Test prototype pack

- Follow trial shipment via “Inter Trak”

- Evaluate analysis of shipping and testing trials

- Implement use and supply

Cost Consultation

Based on the product and the current packaging’s category, size, weight, strength, quantity and destination, we provide the best total packaging solution, designed to reduce cost, rationalize packaging and material handling, and protect your products wherever they are shipped and stored.

Ecology Management

Using our state-of-the-art materials we are able to reduce CO2 emissions (compared to wood packaging) by reducing the weight of the packaging itself, improving logistic efficiency, and in some cases using returnable packaging.

Quality Control

Tri-Wall conforms to premium grade packaging specifications throughout the world. We have our own Research and Development Center in Shanghai and use advanced equipment and technology to perform a variety of key performance tests. Tri-Wall products match and in most cases exceed military and civilian regulatory agency standards worldwide, and conform to all transportation regulatory codes such as IATA, UFC, Rule41, Rule 222, and many more.